The first leg of the trip. (Sorry for the yellow on yellow, but no control over route color)

Well...After the first trip ended after not even an hour, the second try to get the little old lady to Redwood City on Thu March 24th, 2016, was far more successful. This time my friend John joined me for what turned out to be a two-day trip. The first 32 miles (of the total 93 (!) Mile trip got me from Stockton to Pittsburg, all motoring since no-wind (which was fine in this case, since any wind would have been straight ahead and in-our-face).

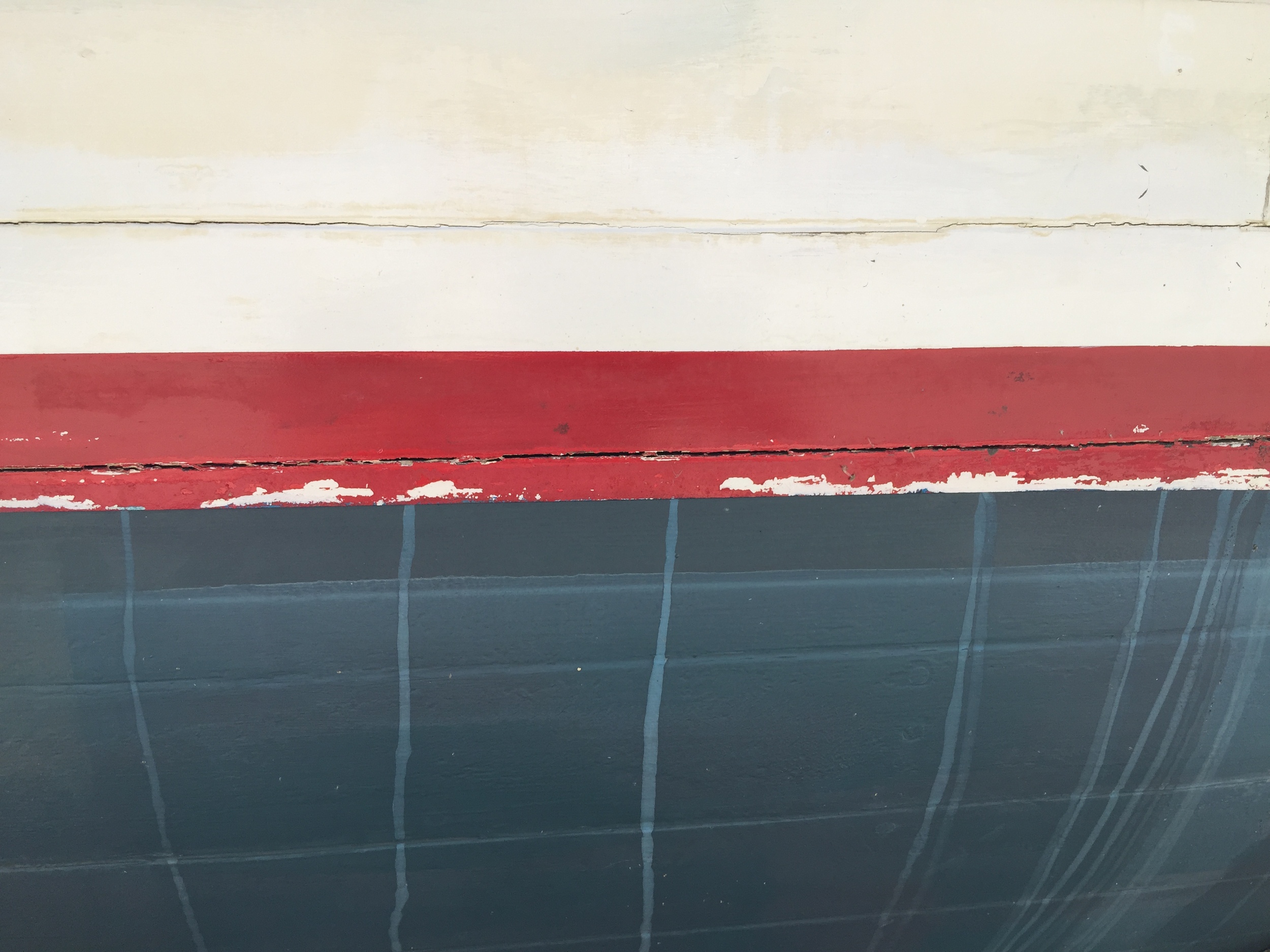

The weather was find and balmy as you can expect in spring in California. The engine was turning over nicely and we're making over 7 knots (almost 13 km/hr) but the first hour or so I was constantly checking the bilge area to ensure we were not making water like the last time we set out. And we didn't...The San Joaquin river and the shipping channel was pretty quite still since it being early in the season etc. and most of the traffic on the river was some fishermen so easy peasy, japaneesey.

John fancies himself a "fun" subject to take pictures of and you'll often find him trying to pose for pictures, specially when his wife is in the frame with him as well, so i got a lot of pics of him doing stuff like this...SIGH...

Anyway...Since I had not thought about filling up the fuel tank when we left Stockton, we were beginning to run on fumes and I started to look around on the sectional (map) for a marina with a fuel dock. I found that the Antioch marina was one of the shockingly few marina's that showed to have a fuel dock. Around 1 PM or so we found the marina and we docked at the fuel station, literally running on fumes (yes, LITERALLY!) but then we read the little note on the fuel station saying "We are sorry to inform you that the fuel station is out of order, while we are working on a brand new system. We expect the new system to be operational in March 2016" (Note we left Stockton on Mar 24th). Since it was still pretty early we figured we could probably talk to the harbor master, so we were impressed to find a phone next to the sign that would allow us to talk to the harbor master. But...also out of order...

Next was a trip to the Harbor master office at the end of the dock and this is when you start to realize the flip side of increased security systems at modern day marina's. Gone are the days that you can simply drive up to a marina and waltz onto the docks without any security gates or nothin'. This marina had a security gate which will open easily without a key from the dock side, but not so much from the shore side. There was no-one around to let us back in, once we left the gate, so we found the phone number for the harbor master and proceeded to call...No answer! Things were not looking up for us...Finally we found a nice lady and we explained our predicament and since she was just going to do her laundry in the laundryroom, she would be able to let us back in if the harbor master was not around. So we went to the harbor master office and then we learned that the harbor master was out for lunch but would be back shortly and indeed, the harbor master ('s assistant) showed up and informed us that indeed they had JUST upgraded the fuel systems but she was not sure if it was operational or not. Informing her that she was our only hope of ever making it to RWC she agreed to let us TRY the fuel pump. She turned on the system and.....SUCCESS! We were saved and filled up the tank to the brim, which takes about 10 gallons (38L) it turns out.

Overview of the first leg of the trip and putting it a little in perspective

Since it was still pretty early and Antioch only brought us about 25 miles closer to RWC (of the 93 miles total trip) we decided to push on as far as John could stomach it (and since he had to get back home that day, we needed somewhere close to a Bart station or other public transportation, which is NOT a trivial issue in California, the land where everyone drives!).

At around 3:28 PM we cruised into Pittsburg marina and found a nice little dock in the marina. Everything sorted with the harbor master for the overnight fee, we set out to find the nice little brewpub and pizza place we read about on Yelp; EJ Phair Brewing Company, and it was walking distance (crawling distance, really) from the Marina!

Having treated John to a beer and a Pizza and putting him on a bus to the Bart station (which took the best part of an hour to get to, apparently) it was a good conclusion of the first part of the two-part trip to Redwood City...

The second part of the trip was going to be twice as long (about 61 miles) but I started off as soon as it was light (around 7 AM). At first, as usual, there was no wind so had to motor all the way to San Pable, but at some point the wind started picking up and it was a perfect South-westerly wind and it thought it would be nice to actually start SAILING this boat, which, until up to that point, has really been little much as an old wooden motorboat (urgh!). Not quite sure of myself, i decided only to use the jib, which is easily unfurled by myself, using the furling mechanism. I was not quite sure if I would be making any speed with just the jib (I should have known better...The jib does most of the work, speed wise) so left the motor on...

WOOOOOOT I'm sailing!

The jib was looking great and soon I felt comfortable turning off the engine and just doing what the Kettenburg was made for!

It wasn't long before the wind died down again so decided to turn the engine back on and roll up the jib, which is easy to do by yourself from the cockpit. It wasn't long when I sighted, what most people in the bay area just call "The CIty" (And NEVER Frisco! San Fran, maybe) (Yes, there is only one REAL city in the bay area and don't even get me started on Oaktown).

Still MILES away, but it definitely is San Franciso!

As you can see, no wind so no jib, but that would soon be different! But first...More pics of the city

Having reached San Francisco, I was still 29 miles from Redwood City and although the wind had picked up, it was straight SOUTH which was the way I was going so not good...It is very unusual to have South wind that late in the day in the Bay, but Spring is still very fickle and the prevailing summer winds (NW after 1 PM, 15-25 knots, typically) had not established themselves yet. But around SFO (the airport) the winds starting shifting again to W to NW which prompted me to unfurl the jib again and save some fuel!

And i also quickly learned "don't film and sail" as you will see. But at this point I was getting close to Redwood City and sailing had put me a little off course, so soon I was motoring again...

Once leaving the bay and entering the Redwood City channel, the Westpoint Marina is still quite a ways away, something I soon grew tired of and prompting me to look for alternative home port but for now I had made it all in one piece and the old lady looked quite happy in her new slip!